Call 1300 205 205

Testing & Tagging

- Master Electrician 10+ years experience

- Full year’s warranty on all parts – that’s the Hit the Switch way

- Local Electricians – Fairer, Better, Right – First time, every time

- Electricians who understand your home is your castle

- Free no obligation advice

Talk to us at a time that suits you

Save the hassle and let us call you to book in a quote.

Talk to us at a time that suits you

Save the hassle and let us call you to book in a quote.

Current Australian and international standards dictate that testing & tagging of portable equipment must be performed according to equipment/cable use and operating environment to ensure the electrical safety of the equipment.

By law, testing and labeling must be performed by licensed or certified competent technicians.

From laptops and mobile phones to power tools and kitchen appliances, portable devices and appliances are everywhere in our daily lives. However, if these devices are not regularly tested and maintained, they can pose serious hazards such as electric shock, fire, and other accidents. Testing and tagging can help here. This article explores the importance of testing and tagging portable appliances, legal requirements, testing processes, benefits, and more.

Introduction

Testing and tagging is the process of inspecting, testing and tagging portable electronic devices to ensure their safety. Thus, this includes both visual inspection and electrical testing to identify possible faults and hazards. The main purpose of testing and tagging is to minimize the risks associated with using portable appliances and protect both people and property from harm.

Legal Requirements for Test & Tagging

Many countries have specific regulations and standards to ensure electrical safety, and Testing & Tagging are often legal requirements for companies. Therefore, complying with these regulations is essential to avoid penalties and legal obligations. It is important for businesses to understand their obligations and follow established inspection intervals and procedures.

The Testing Process

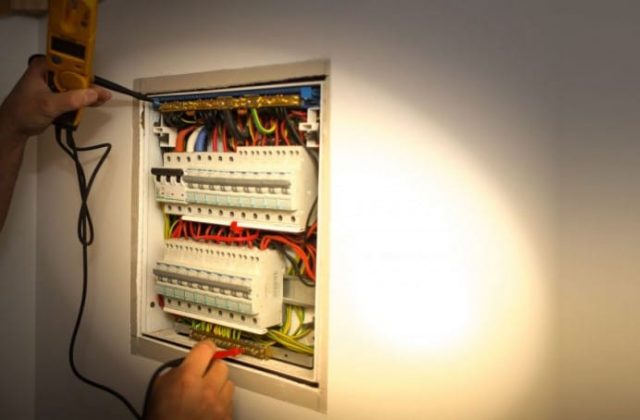

The Test & Tagging process usually consists of two main components: 1) visual inspection and 2) electrical inspection. Firstly, visual inspection examines the external condition of the appliance, including cables, plugs, and housings, for visible damage or defects. Secondly, electrical testing uses specialized equipment to evaluate various electrical parameters such as insulation resistance, earth continuity and polarity.

Types of Portable Appliances

Portable appliances come in many forms, from low-risk devices such as lights and radios to high-risk equipment such as power tools and industrial machinery. Different test requirements apply to different device/appliance types depending on their risk level. Thus, properly categorizing and prioritizing appliances is important to ensure that they are properly tested and tagged.

Benefits of Test & Tagging

Test & Tagging have some important benefits, especially when it comes to security and safety. Regular testing and tagging of portable devices can greatly reduce the risk of electric shock, fire, and other accidents. Individuals and businesses alike can rest assured that their appliances are safe and reliable.

Who Should Perform Test & Tagging?

Test & Tagging must be performed by qualified personnel with the required knowledge and skills. Electricians and certified testing and tagging professionals are usually experts in this task. As expected, they have the ability to identify potential electrical hazards and ensure that equipment and appliances meet safety standards.

Record Keeping and Documentation

Maintaining accurate records of Test & Tagging is critical for regulatory compliance and traceability. These records should include details such as the date of the test, who performed the test, and the results of the test. Consequently, documentation helps track the history of each appliance, making it easier to identify potential issues and prove compliance.

Test & Tagging Equipment

For thorough testing, professionals use specialized equipment such as portable appliance testers (PATs), insulation resistance testers, and earth loop impedance testers. Regular calibration and maintenance of these test devices is critical to ensure accurate and reliable results.

Implementing a Test & Tagging Program

Organizations should establish a comprehensive Test & Tagging program to ensure ongoing safety and compliance. This program includes developing a testing plan, identifying responsible personnel, providing necessary training to employees, and establishing procedures for dealing with test failures and equipment or appliance defects.

Outsourcing Test & Tagging Services

For companies with limited resources and expertise, outsourcing Test & Tagging services can be a viable option. When you hire professional testing and tagging services, you benefit from our expertise, experience and state-of-the-art equipment. This allows companies to focus on their core business while making sure that their portable appliances are safe.

Test & Tagging for Different Environments

Different environments present unique challenges when it comes to Test & Tagging. For example, construction sites may require more frequent testing due to harsh conditions, while lower-risk workplaces may focus on computers and stationery or fixed electrical equipment. Compliance requirements may also vary depending on the level of risk associated with each environment.

Conclusion

Test & Tagging is an important process in ensuring the safety of portable appliances. By complying with legal requirements and performing regular testing and tagging, individuals and businesses can significantly reduce the risk of accidents, personal injury and property damage due to equipment or appliance defects. To create a safe environment for everyone, electrical safety should always be a top priority.

Get in touch to see how we can help you!

Contact us today